![]() Material Powder

Material Powder

The product is mainly made of various metal powders as raw materials. According to the different manufacturing processes, the operation of the sintering process affects the mechanical and physical properties of the product. Therefore, suitable raw materials should be selected based on the usage and characteristic requirements of the product.

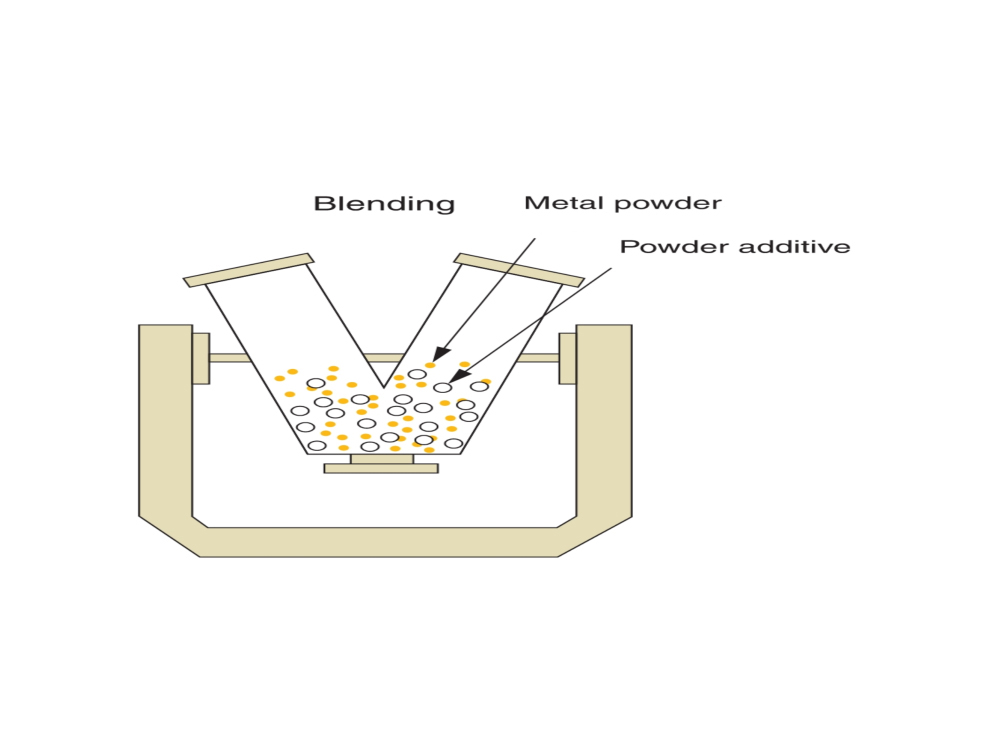

![]() Blending

Blending

Use a mixer to evenly mix different metal raw material powders such as Fe, Cu, Sn, Zn, etc. together.

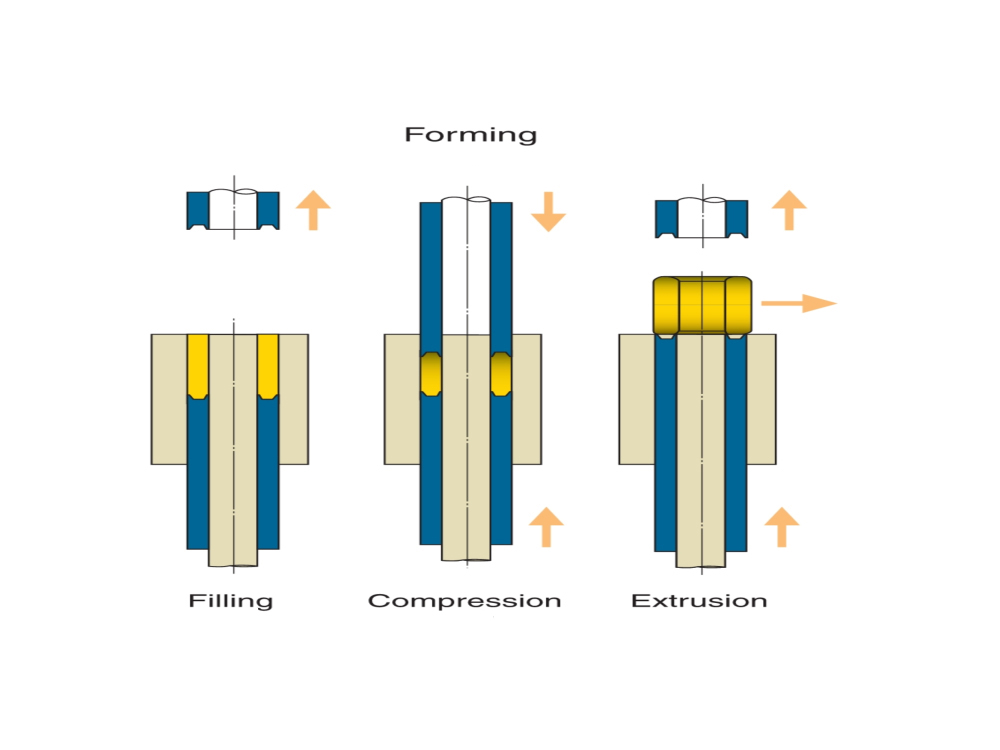

![]() Forming

Forming

Use a molding machine to compress the mixed metal powder from top to bottom through a mold, giving it shape, size, and density.

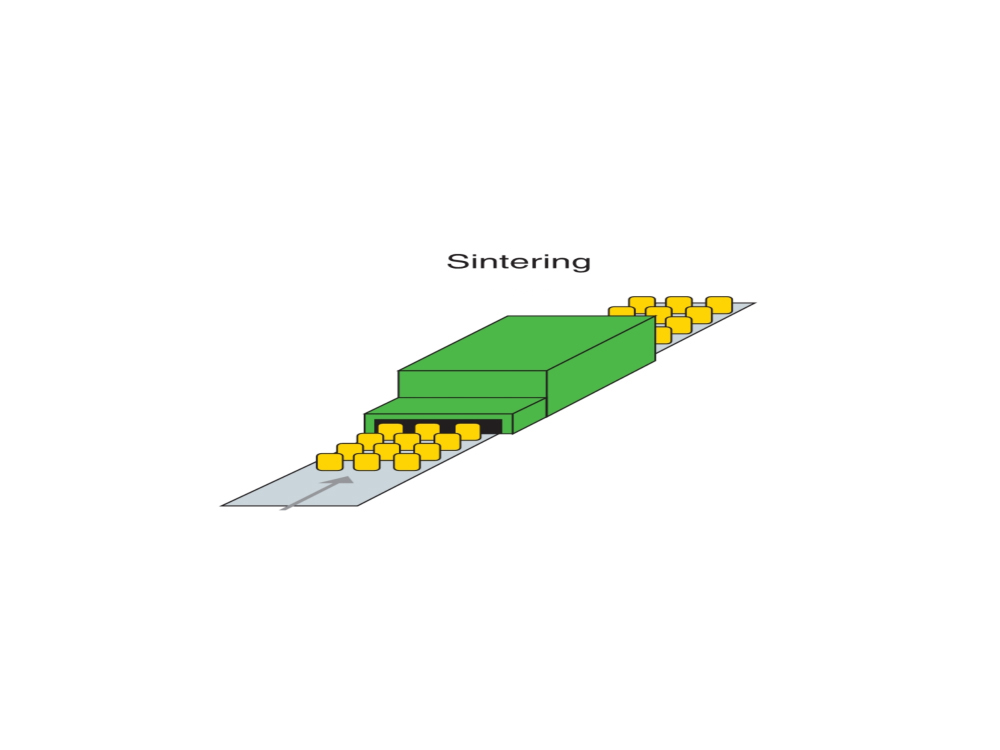

![]() Sintering

Sintering

Heat the compressed powder formed according to the sintering temperature of the material, and combine the metal particles of the formed body to improve strength.

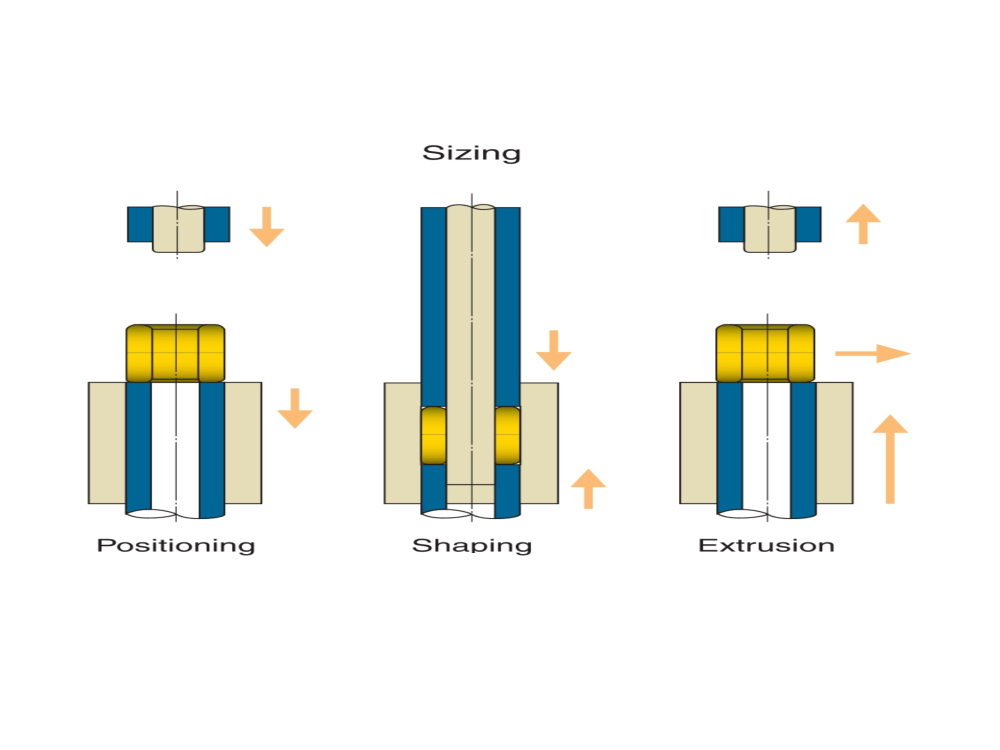

![]() Sizing

Sizing

Put the sintered product back into the mold for compression to obtain high-precision dimensions and shapes.

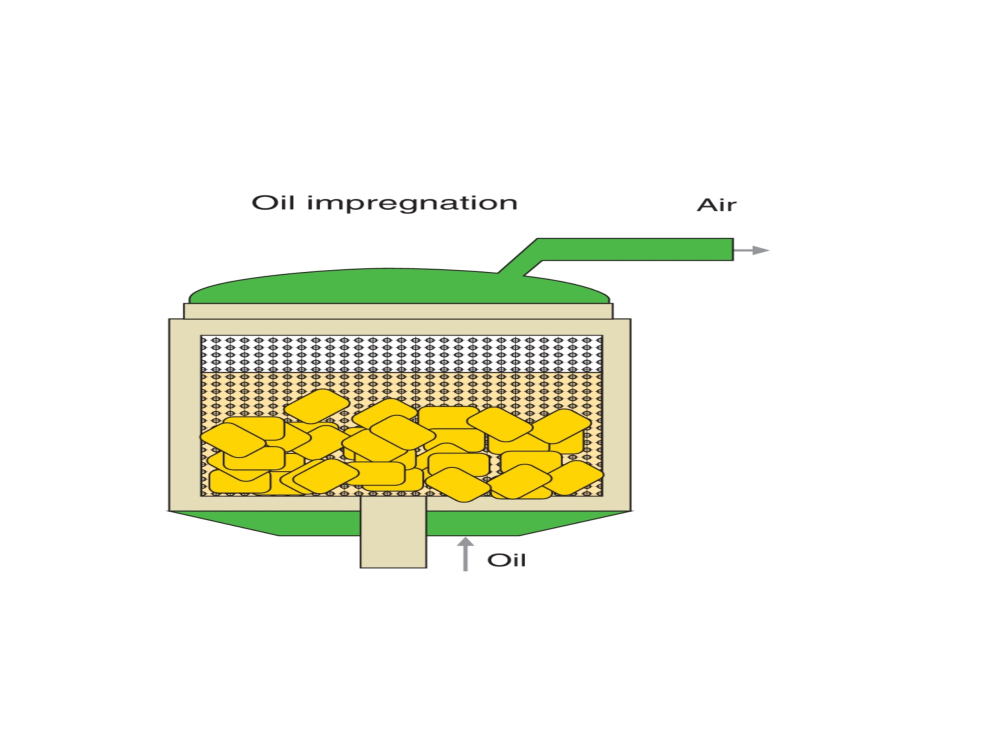

![]() Vacuum oil-impregnation

Vacuum oil-impregnation

Place the shaped product in a vacuum immersion cylinder, first seal and depressurize the air inside the product, and then guide the oil into the workpiece to immerse it.